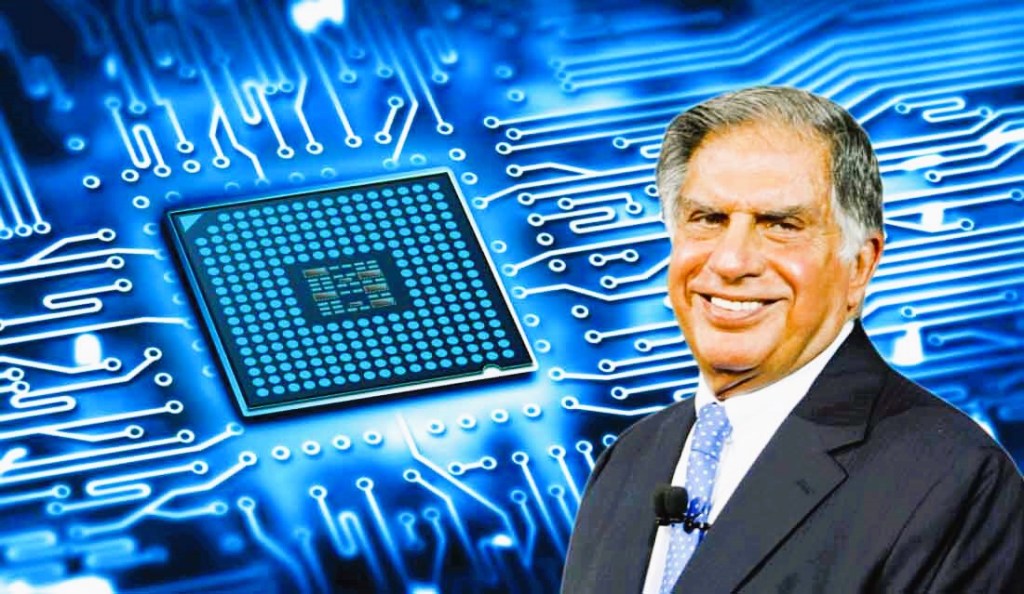

The Indian government approves Tata Group’s ground breaking project to establish India’s first semiconductor fabrication plant, paving the way for technological advancements in various industries.

In a ground breaking stride towards technological autonomy, India is poised for a transformative leap with Tata Electronics Pvt Ltd’s (TEPL) semiconductor fabrication plant in Dholera, Gujarat. With a staggering investment of 91,000 crore rupees, this ambitious project heralds a revolution in India’s semiconductor industry, propelling the nation towards an era of innovation and self-sufficiency.

Tata Motors and Tejas Networks Ltd, in collaboration with Taiwan’s Powerchip Semiconductor Manufacturing Corp (PSMC), spearhead India’s foray into semiconductor manufacturing. This strategic partnership underscores Tata’s commitment to advancing indigenous semiconductor solutions, aligning seamlessly with India’s growing demand for homegrown technology.

Government’s approval of the semiconductor fab facility is a watershed moment in India’s technological landscape. Estimated at 1.26 trillion rupees, the plant is set to be South Asia’s largest, producing a remarkable 3 billion chips annually. This monumental endeavour signifies a quantum leap, diminishing India’s reliance on imported semiconductor components.

Despite challenges like a lack of a robust ecosystem and skilled manpower shortages, India’s semiconductor industry is poised for exponential growth. With industry leaders like HCL Technologies, Vedanta, Tata Elxsi, Dixon Technologies, and MosChip Semiconductor, India stands on the cusp of emerging as a global semiconductor powerhouse.

Serving as a cornerstone of economic growth, the semiconductor industry contributes significantly to job creation, attracting investments, and enhancing GDP. India aims to bolster its global position in technology by nurturing this sector, fostering innovation across various industries.

High initial investment and a shortage of skilled manpower pose significant challenges to semiconductor manufacturing in India. However, concerted efforts and government initiatives strive to overcome these hurdles, unlocking the full potential of India’s semiconductor industry.

Valued at approximately $23.2 billion, India’s semiconductor market is poised for exponential growth, driven by increasing demand in smartphones, automotive, and data storage. Semiconductor manufacturing is not only crucial for economic growth but also for fortifying strategic sectors like defense and communications.

The global semiconductor shortage underscores the critical importance of self-reliance. With India’s semiconductor industry expected to grow at an annual rate of 8.31%, the nation is well-positioned to address supply chain disruptions and reduce import dependency.

India’s aspiration to become a semiconductor hub is backed by government initiatives, including a production-linked incentive scheme worth 76,000 crore rupees. These efforts aim to catapult India into a global semiconductor powerhouse, fostering innovation, creating jobs, and driving economic growth.

Tata Group’s semiconductor fabrication plant represents a transformative milestone in India’s quest for technological self-reliance. With the capacity to produce 3 billion chips annually, this monumental project not only enhances India’s semiconductor capabilities but also unleashes a wave of innovation. As India charts a course towards becoming a global semiconductor hub, Tata’s visionary initiative stands as a beacon of progress, heralding a future of unparalleled technological advancement and economic prosperity for the nation.

visit arjasrikanth.in for more insights